Here’s a quick guide on how to disassemble and clean a Turnigy Park450 brushless motor. This is a very well made and very strong motor for your RC plane. If you want this motor you can buy it here from HobbyKing:

Turnigy Park450 Brushless Outrunner 890kv

Turnigy Park450 Brushless Outrunner 1050kv

Turnigy Park450 Brushless Outrunner 1200kv

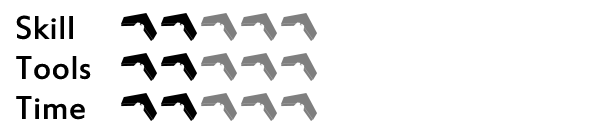

What You'll Need

- Small Philips Screwdriver

- 2mm (I think) Allen Key

- Soft Brush

- Soft Cloth

- Rubbing Alcohol

Disassembling the Motor Remove the motor from the airplane. I had this motor on a FunBat, but I didn’t have any wheels on it, so I landed on the beach where I was flying and got some sand in my motor. The motor made a grinding/crunching sound when turned by hand.

Remove the four screws on the mount.

Using an allen key, loosen the two grub screws that hold the lock in place.

Grip the base firmly, and pull off the bell of the motor.

Cleaning the Motor

There is the sand - clean it off with a soft cloth or a brush. Use alcohol if you need something liquid to aid cleaning.

Notice the remaining spots, I think they are rust, and they will be hard to remove.

Add some oil to the bearings, to lubricate them and to prevent further rusting. Do the same with the bearing on the underside of the motor.

Reassembling the Motor

Carefully slip the bell back on, the magnets should pull it in place. Just be careful so you don’t knock out the bottom bearing.

Put the lock back on the axle, but make sure the little dent in the axle is perpendicular to the grub screw in the lock - otherwise you’ll get a dodgy fit. Press in the lock as far as it’ll go.

Tighten the grub screws back in place. You might want to use blue threadlock for more safety.

Reinstall the mount. If the holes don’t line up, rotate the mount by 90º.

Reinstall the motor in the aircraft, making sure you do it well. Reattach the spinner with the propeller.

Done!

Author:

André Elb aka ColoreX

Log In to reply

I want to build either a Diablo 3D foamie with it or a scratchbuilt 1000mm balsa Extra 300S.

Log In to reply

Log In to reply

Log In to reply

Log In to reply

When oiling the bearings use a light machine oil.

Some LHS carry a bearing specific oil that has a long needle for an applicator. Makes getting the oil into the right places easy.

I've seen the same applicators sometimes on sewing machine oil- would work great for this application too.

Log In to reply

And when you live in Ecuador and don't have a regular job, you have to stick with what your mom has. :D

Log In to reply

Log In to reply

Log In to reply

Log In to reply

Log In to reply